.fundamentals for future makers

.01 pre-course experience: first contact with the Fab Lab machines and the basics with Barduino

My experience started during the pre-course sessions in September 2025.

That was my first structured introduction to digital fabrication workflows, and it helped me connect the dots between

designing something digitally and actually producing it physically.

We explored several key machines and processes: CNC milling, laser cutting, vinyl cutting, and 3D printing.

Alongside the machines, we also explored the inputs and outputs course, where we started learning how to work with

a Barduino. We introduced basic concepts like signals, sensors, and actuators, and how simple interactions can be built by connecting

input data to output behaviors.

.02 main course: CNC box, 3D tile, silicone mold

What I loved most about this course is that it felt deeply manual.

We started by producing a box using the CNC machine. That step taught me a lot about precision, tolerances,

and the importance of planning.

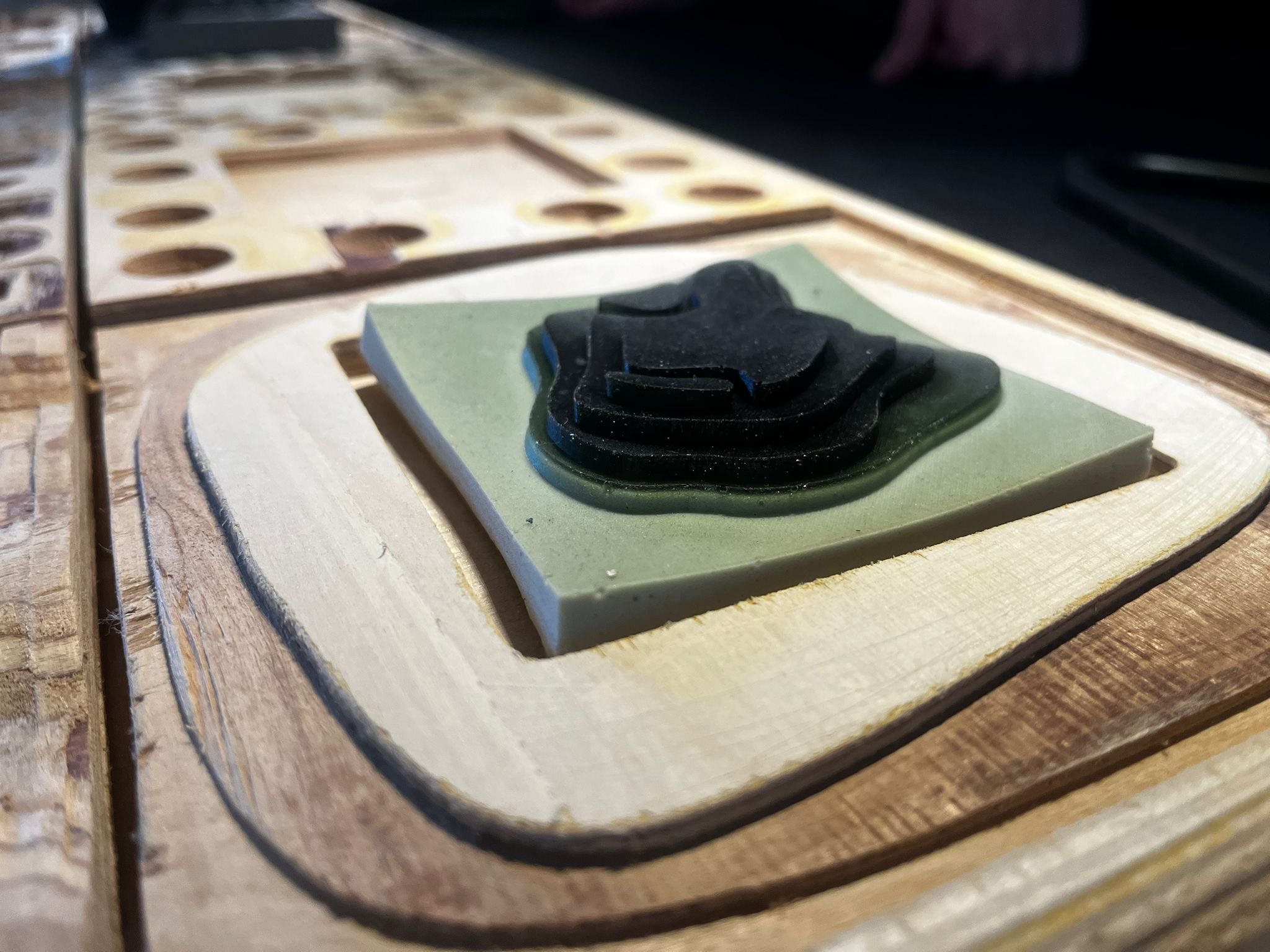

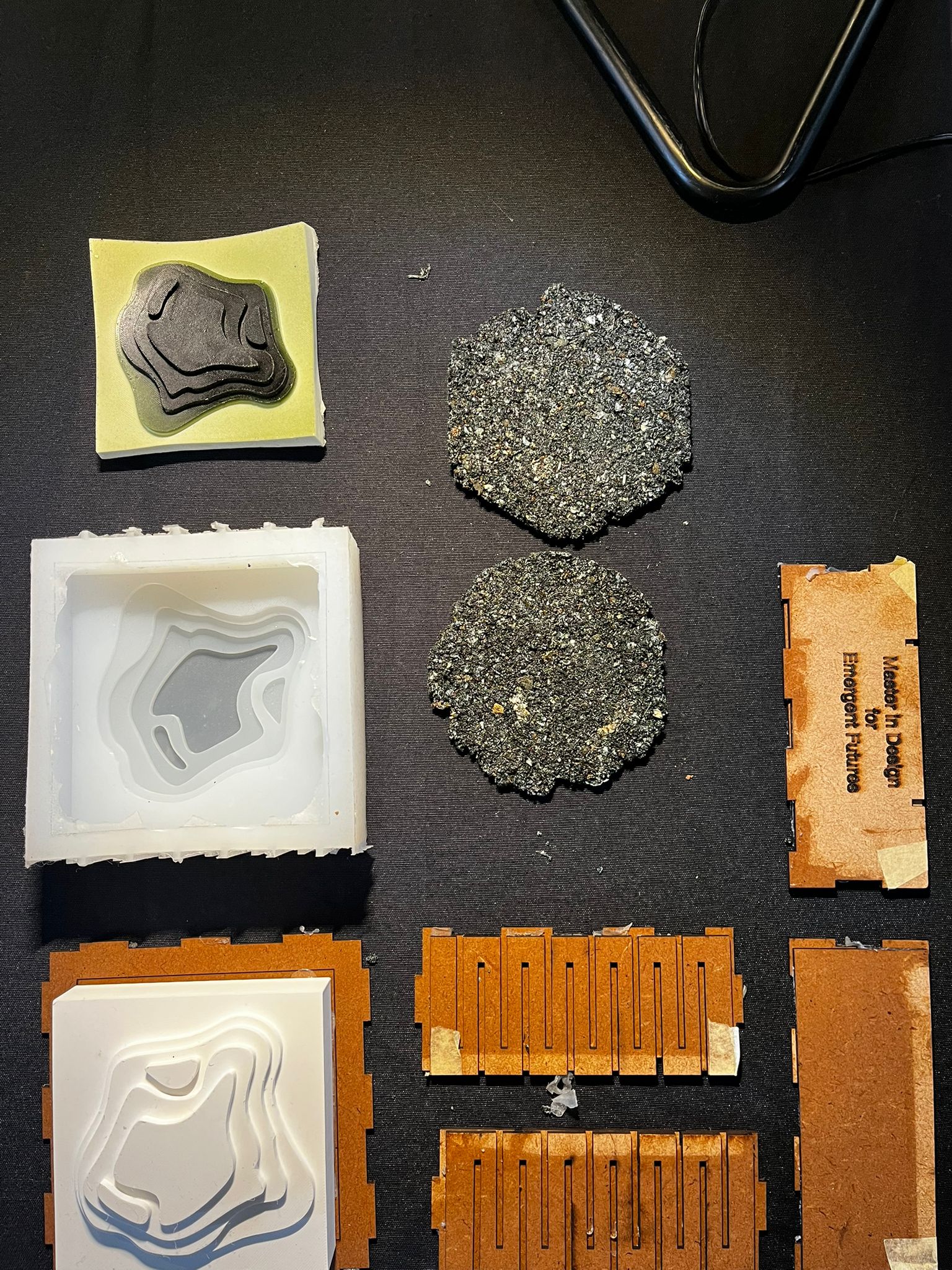

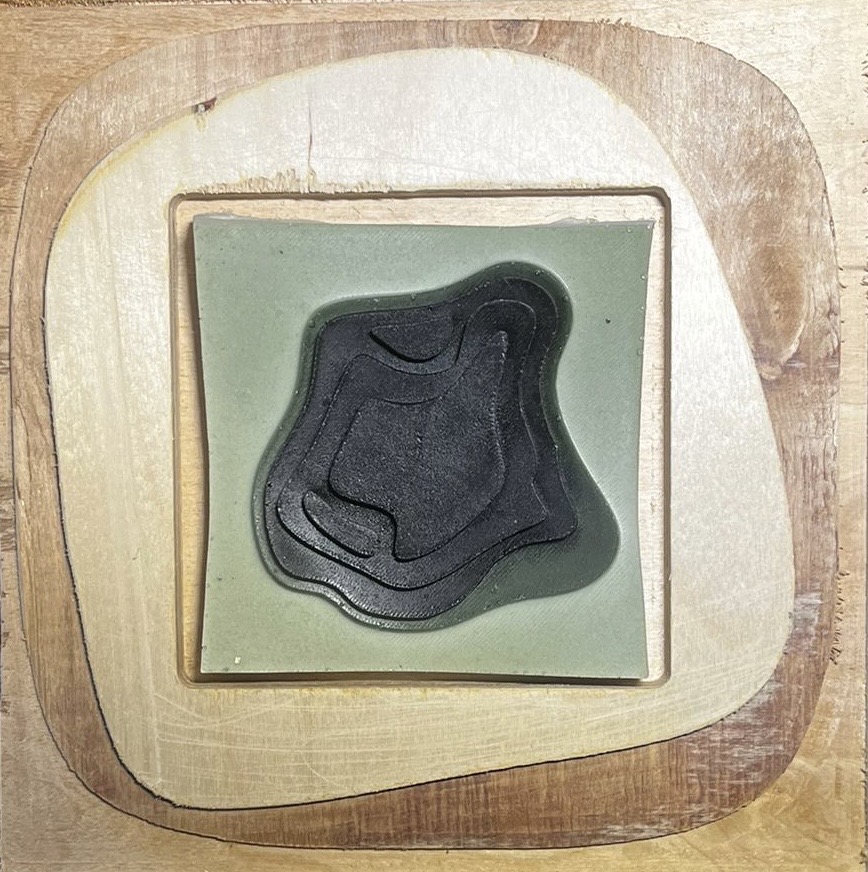

After that, we designed and 3D printed our own tile. The idea was to use the printed piece as a positive element.

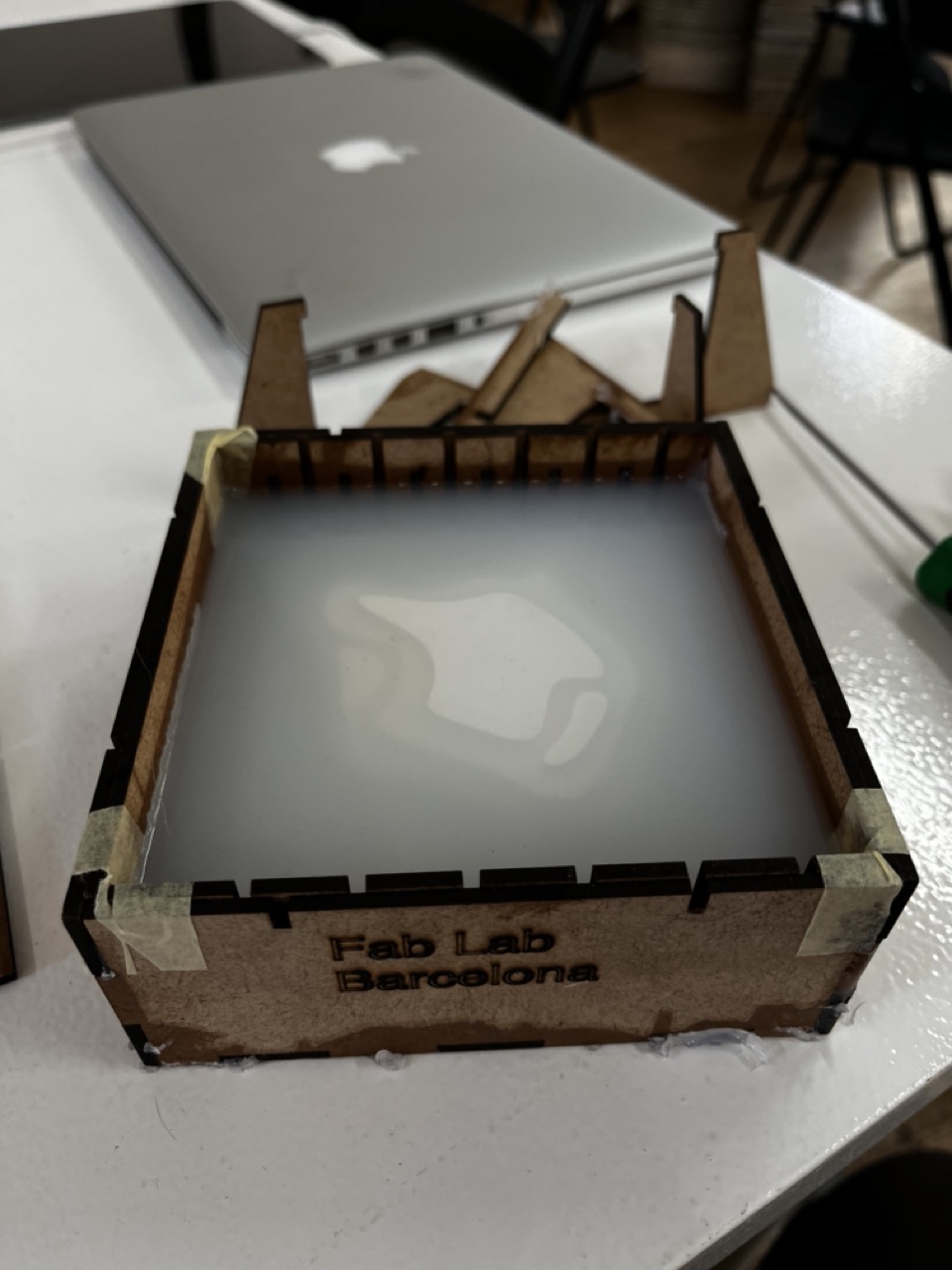

Once the tile was ready, we placed it inside the CNC-made box and poured silicone over it.

Watching the silicone set felt like a slow reveal, and when we finally demolded it, we ended up with a negative mold:

ready to be used for casting and experimenting further.

.03 biomaterials workshop

This was one of my favorite moments was the biomaterials workshop.

I already have independent experience with biomaterials, so it was exciting to bring that background into a shared lab context.

During the workshop, I developed "gelatine foam": a recipe based on gelatin, dish soap, and spirulina.

The result was really interesting and I experimented again the same recepice in the BioLab by myself for a futher exploration.